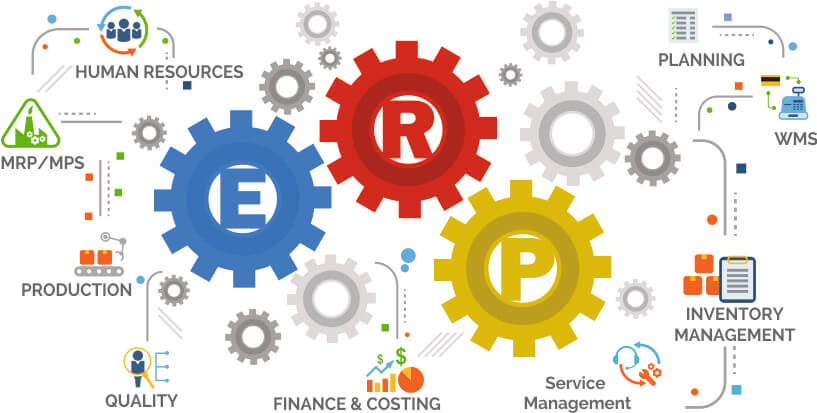

ERP software provides some of the most up-to-date modules for manufacturing businesses today. ERP modules for manufacturing industry help you meet the business requirements by creating a complete production scenario including routings and bills of materials. It also makes it easy to manage finances and costing by generating a comprehensive financial picture while also serving as a seamless project and inventory management system.

Listed below are a few basic modules that are required in an ERP solution for a manufacturing business. Learn how these basic ERP modules help to quickly improve business processes.

Automate business processes in a more systematic way using the Production Module

Are you looking for an enterprise solution where every department is integrated into one system? If so, an Enterprise Resource System can manage all of your business processes effortlessly using one database for a single version of the truth.

Taking full control of your business processes and not allowing repetition of entries is possible only when you allow technology to take control instead of manual entries. An ERP solution takes care of production needs such as managing bills of materials (BOM), routings, shop floor execution, materials requirement planning, and production orders to help you accurately assess needs and produce balanced and economic outputs.

Some of the basic advantages that your business gets by using the Production module are production planning, defining factory capacity, allocating orders, and tracking all of your orders. You can also respond to customer demand and create sales forecasts. Designed for the specific needs of the manufacturers, the production module includes core capabilities facilitating overall production planning to delivering products to customers.

Give perfection to the business with the Quality Module

What manufacturing business doesn’t want dynamic quality control in their everyday business processes? A good ERP solution will ensure you receive precise quality for every product to increase satisfaction and customer retention.

Get clear visibility into every phase of your operations, from receiving raw materials, through the production of finished goods, to inspections of finished goods before dispatching. The fully integrated quality control manages the record of pass/fail statistics and assists you to accept or reject the product based on inspection results. This ultimately lets you gain insights into costs and process efficiency.

Get going quickly from vision to execution with the Planning Module

The Planning module involves forecasting based on production criteria such as the weighted average, multi-level production planning, inventory, material planning, capacity planning, etc. It allows all of the manufacturing orders to be scheduled automatically depending upon reordering rules, incoming quantities, and the overall demand. It provides insight into inventory and orders in real-time.

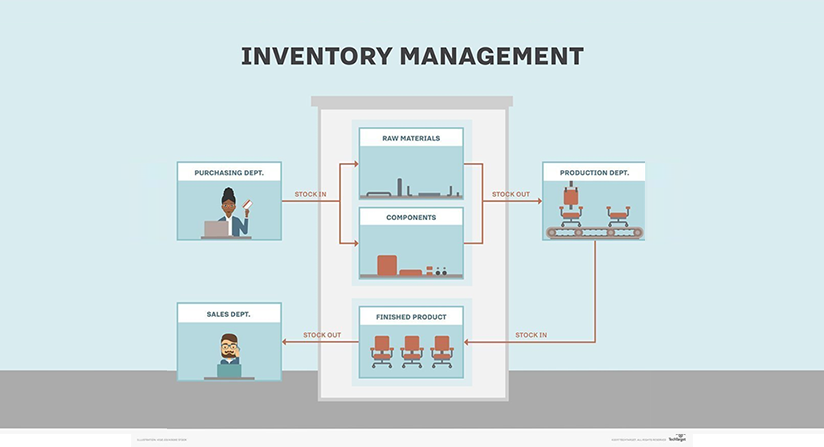

Decide with fewer limitations and more insights with the Warehouse Module

With an ERP system, your business can seamlessly manage all of its finances, logistics, inventory, and everyday operations in one place. The warehouse management module controls the daily operation of warehouses including taking care of orders and work monitoring. This module provides accurate, real-time information on inventory. Manufacturing businesses need a unified method to monitor the overall implementation of warehouse orders. The warehouse management module supports inventory planning and preparation for increased costs savings and supply chain transparency.

Productivity and transparency are necessary for today’s competitive marketplace. Closing the productivity gap requires the technology that comes with an ERP system. It can accelerate innovation and add value to your high-tech manufacturing business.

Having a manufacturing ERP that is specifically designed for your industry needs can be more effective than a generic ERP system and provide your business the necessary boost to better compete. To learn more about ERP modules for manufacturing industry, contact us for a free demo.

Follow Us