Quality management is embedded within core lean manufacturing principles, however improving quality assurance even further for small and large manufacturers alike, can be achieved by adopting Six Sigma techniques and strategies.

Lean manufacturing is a philosophy of continuous improvement (kaizen) with the goal of providing extraordinary value to the customer through a process of eliminating waste, (activities that do not add value), from every aspect of the operation. True lean manufacturing principles encourage every individual in the organization to continuously improve value generating activities and eliminate non-value generating activities. The principles are laser-focused on increasing company efficiency.

The Origin of Lean Manufacturing

Lean manufacturing originates from the Toyota Production System, sometimes known as Just In Time (JIT) production, which Toyota devised post World War II. They took the best out of Henry Ford’s mass production techniques and shaped them to meet their own needs. Toyota reduced manufacturing batch sizes and encouraged their employees to become active members of the production process. This resulted in increased efficiencies and higher quality products, which in turn increased customer satisfaction.

As the philosophy evolved American manufacturers in the 1980s adopted some of the processes which in turn evolved into what we now know as lean manufacturing principles.

Lean Manufacturing Quality Management Principles

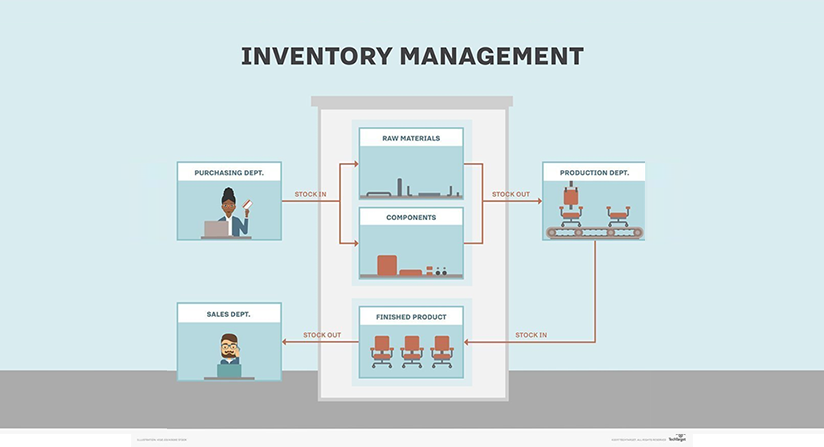

Although lean manufacturing is best known for its JIT production efficiencies it also embodies a set of quality management principles. JIT production requires one smooth continuous flow from raw materials to finished goods. It does not allow things to be done a second time as any stoppages introduce waste and are to be avoided at all costs. Lean manufacturing principles, therefore, strive for quality built into product and process design. Mis-assembly errors are reduced or eliminated by mistake proofing (Poka-yoke), and intelligent automation (Jidoka) will detect process malfunctions or product defects immediately and automatically shut down a machine.

Improving Quality Assurance With Six Sigma

However many small and large lean manufacturers are improving quality assurance further with the adoption of Six Sigma techniques and strategies. Whereas “lean” can be described as a philosophy and set of principles, Six Sigma is a problem-solving methodology. Originally developed by Motorola engineer Bill Smith in the 1980s it has become a gold standard quality measure in manufacturing.

The term Six Sigma derives from a statistical principle that states – if you start at your process mean value and you eliminate defects within six sigma of the mean and nearest specification limit, you will virtually eliminate all defects or errors. If you do the math that means less than the 3.4 defects for every 1 million opportunities.

The Six Sigma methodology defines, evaluates and improves every step in a process with the goal of producing reliable and consistent results free of defects. It emphasizes the simplicity of the process, quality of parts and supplies, and employee responsibility for achieving promised results.

The 2 Primary Six Sigma Methodologies

Six Sigma Daily outlines the two main methodologies in this manner:

DMAIC: This method is used primarily for improving existing business processes. The letters stand for:

- Define the problem and the project goals

- Measure in detail the various aspects of the current process

- Analyze data to, among other things, find the root defects in a process

- Improve the process

- Control how the process is done in the future.

DMADV: This method is typically used to create new processes and new products or services. The letters stand for:

- Define the project goals

- Measure critical components of the process and the product capabilities

- Analyze the data and develop various designs for the process, eventually picking the best one

- Design and test details of the process

- Verify the design by running simulations and a pilot program, and then handing over the process to the client

Does It Work?

The ultimate goal is to improve every process to a “six sigma” level or better. Does it work? Motorola reported in 2006 that the company had saved $17 billion using Six Sigma.

Lean manufacturing principles and Six Sigma methodologies complement each other extremely well. The combination of efficiency gains from the application of lean principles, and quality gains from the data-driven Six Sigma approach can boost manufacturing performance, deliver significant cost reductions and produce higher quality output.

Follow Us