Predicting future demand contributes to making well-informed organizational decisions.

Forecasting helps businesses plan for future endeavors by evaluating historical data and analyzing trend patterns. It is the process of extracting information from past and present data to make diligent decisions regarding purchase, sale, inventory and other departments.

Before planning the production process, it is critical to estimate future business conditions. Organizations should anticipate future demand for enhanced business management.

Many factors influence demand. Often, it is not possible to identify all of them or the effects they have. Some of the major demand influences include:

- Business and economic conditions

- Competition

- Market trends

- Company plans for products, pricing, and promotion

Other sources of demand include:

- Spare parts

- Promotions

- Intracompany demand

Forecasting helps you create projections of expected demand. The projections can include estimates for one or more products.

Traditional forecasting, never delivers precision which ultimately leads to shortfalls and gives rise to new business challenges. Past records alone can never predict and represent the future of any organization.

Without the ‘smart technologies’ found in modern, intelligent ERP systems, aging equipment, changing technologies, maintenance practices and other modifications in the manufacturing sector cannot be predicted beforehand. These are some of the reasons for the shortfalls of traditional forecasting. The traditional forecast does not accurately represent and measure future metrics in detail.

Every modern manufacturer, seeks better operating capacity, reduced costs, and increased profits. Compared to historical forecasting methods like traditional time-series forecasting, innovative methods like trend models, segmentation, regression, exponential smoothing, moving average offer more accuracy making it sensible to replace traditional forecasting with smart, precise and mature predictive models based on sophisticated technology. It encourages smart and diligent decision-making for the future.

Difference between intelligent forecasting and traditional forecasting is explained below.

| Intelligent Forecasting | Traditional or Non-intelligent Forecasting |

|---|---|

| Generates detailed future metrics that state possible outcomes to plan new strategies, encounter past challenges and enable businesses to make well-informed decisions. | Limited to evaluating the history of data. The result may create a gap between forecast and actuality. Future is not always equal to the past so it’s difficult to predict it manually. |

| Includes complex, probabilistic age modeling offers graphical user interface to users. It does not require over-simplifying assumptions. | Requires over-simplifying assumptions for inputting of data. With static time models, it is difficult to predict the future accurately. |

| Supports sophisticated analysis with statistical calculations – in real-time. Calculation methods are automatic. | With manual methods of forecasting, chances of errors and redundancy are greater. |

| Built-in models based on statistical calculations allow the organization to predict seasonal demand and future trends. | Traditional forecasting depends entirely on the analysis of past events. It cannot help businesses predict the future accurately. |

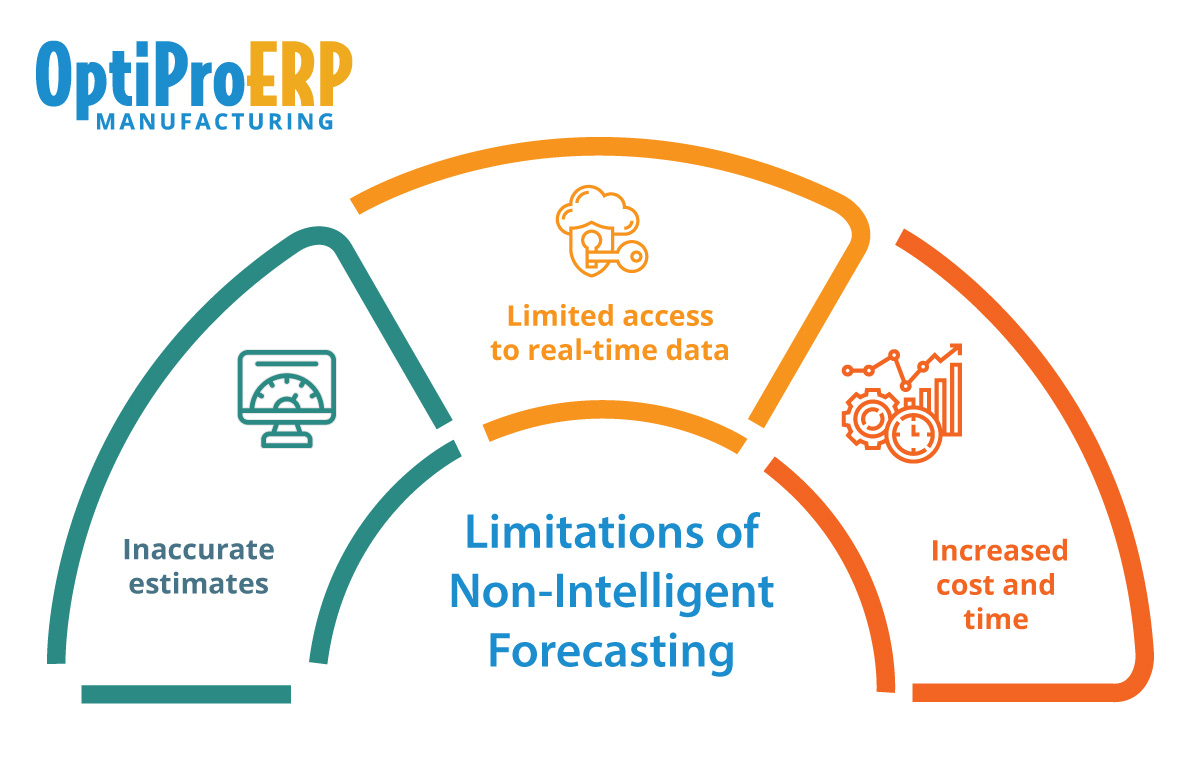

Let’s have a look at the limitations of non-intelligent or traditional ways of forecasting in manufacturing –

1. Estimates don’t work

Before technologies such as Blockchain, AI, Big Data, etc. evolved, forecasting was done manually by analyzing time series data (from previous years, months, quarters).

The future is unpredictable. Even if you use the best forecasting methods to predict future events, it will never be 100% correct. This is the reason why manufacturers are investing in modern algorithms which work on mathematical models. It can automate the forecasting process, save time and improve accuracy.

2. Limited access to real-time data

This is the internet-driven world where people work remotely from different corners of the world. When an organization doesn’t use cloud technology and still relies on traditional ways of working, it limits the data that can be considered for forecasting.

Imagine, your production plant is in location A and your procurement team works from location B, how will you bridge the gap between the two? When you don’t have access to remote working and analytics tools, it becomes difficult to bring your business data together. If you don’t know the status of data of different departments, how can you track work, evaluate past events and compile it? It directly affects your decision-making processes.

When you are using non-intelligent ERP software, remote tracking and real-time availability of data are not possible.

3. Increased cost and Time

Collection and tabulation of data in a manual way can take many resources and plenty of money.

What is an intelligent forecast?

With the evolution of smart technologies and new algorithms, the scenario for modern forecasting is different.

Intelligent forecasting lets organizations take business decisions with confidence. With advanced analytics capabilities and predictive services, intelligent software can help you time your purchases to fulfill your sales orders. Intelligent forecasting allows organizations to discover patterns in data. This helps them anticipate what is likely to happen in the future and make data-driven plans.

Built on a user-friendly interface, modern ERP solutions assist manufacturers to select their forecasting period and obtain the results online. Let’s look at the advantages of intelligent forecasting.

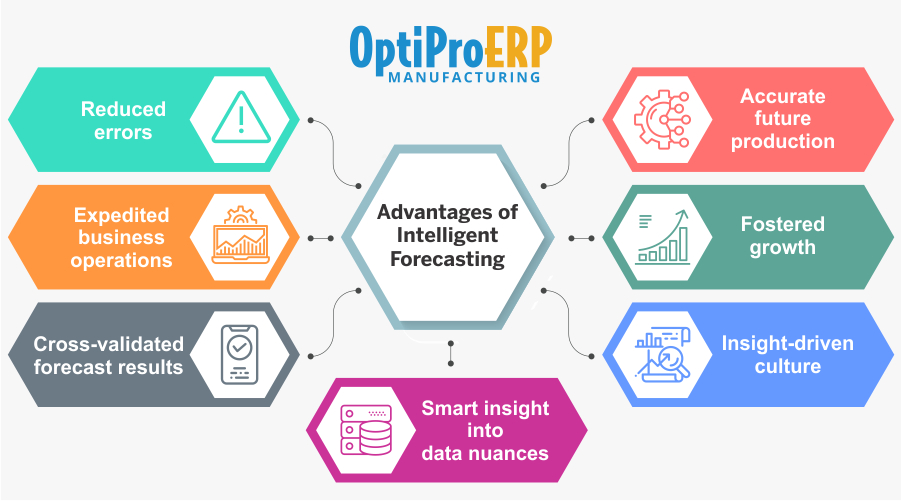

1. Explore data nuances with smart insights

With intelligent forecasting features available in modern ERP, you can use natural language and visual explanations that can simplify the most complicated set of data & nurture clarity. Machine learning and demand analytics allow financial planners to manage and compare the limitless amount of data to minimize data redundancy and promote efficiency.

2. Create an insight-driven culture

Production forecasting software systems give businesses quick access to departmental data with ‘search to insight’ features and conversational AI. It lets you generate visualizations in real-time to understand underlying business trends for the future.

3. Cross-validate forecast result

Intelligent forecasting can considerably increase forecast accuracy. Users can cross-validate forecast results and access large-scale data sets and manage them in a library of state-of-the-art models. You can use hindsight to previous actual values on the basis of algorithms.

4. Predict the future with accuracy – foster growth

When data is stored on a single platform and is organized properly, forecasting becomes hassle-free. Intelligent ERP helps the organization choose a definite course of action with the purpose of fostering growth and success.

5. Less errors and expedited operations with statistical methods

SAP Business One uses statistical methods to evaluate large chunks of business data and historical events. Embedded with Big Data technology, SAP Business One Hana empowers you to visualize the information in insightful charts for easy viewing and manage the data in real-time.

SAP Hana is in-memory relational database management system that gives you ultimate control over your organizational data. With Big Data analytics, it gives you crystal clear visibility to your departmental data.

How does Intelligent Forecasting work in OptiProERP?

Built on SAP Business One, OptiProERP is one of the trusted ERP software solutions that offers a forecast and MRP planning system to help production planners manage production using defined parameters.

In addition to planning for received orders, OptiProERP with SAP Business One allows users to foresee the future and predict demand based on the multi-level forecast.

Let’s see how it actually works in OptiProERP.

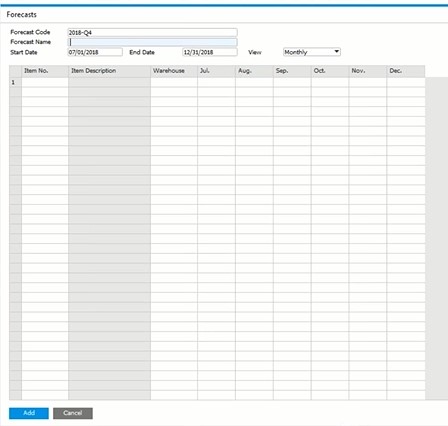

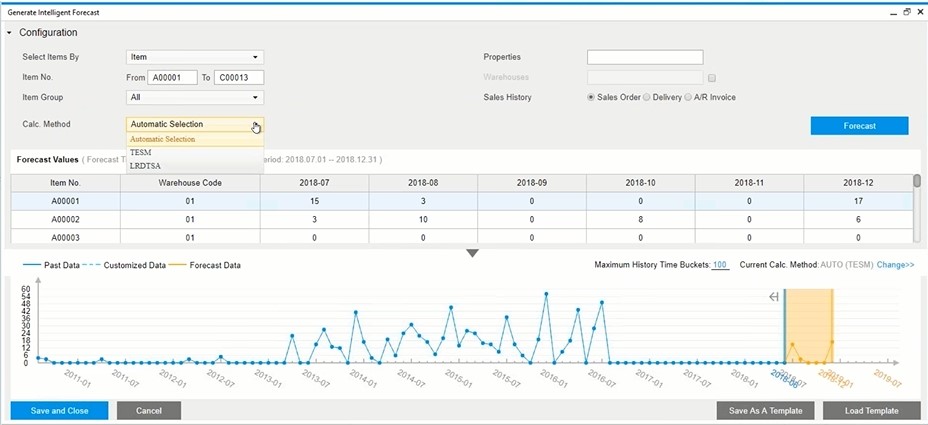

Let’s say you are a procurement manager and you want to forecast for the next season. You typically establish a forecast for the next quarter. We open the forecast screen and give it a code and name.

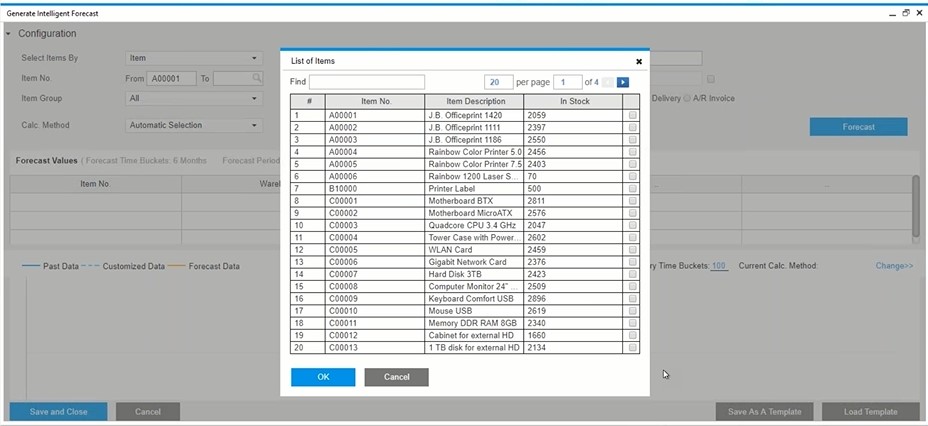

We select a range of items, and click forecast.

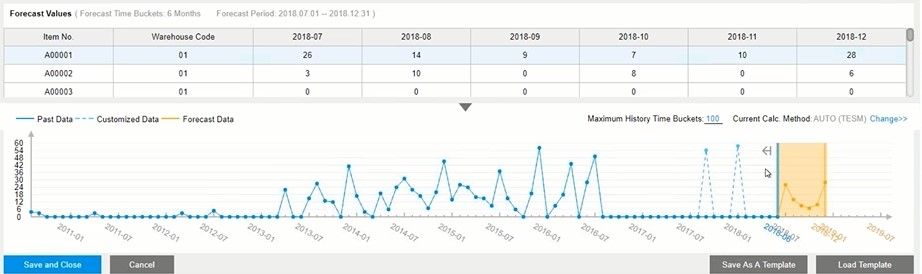

The system is looking at the history and generating the forecast. By default, we use a triple exponential smoothing. You also have Linear Regression, and others. The system generates the forecast in a graphical mode.

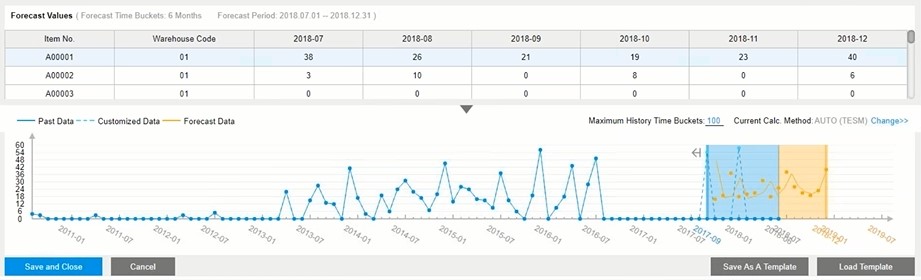

In the graph, you can take any graph point and drag it up or down to change the forecast, to maybe represent sales promotions in that period. Note the forecast values change automatically in the grid.

If you only want to consider inventory movements for the last year, you can drag the blue section across and the forecast is updated dynamically.

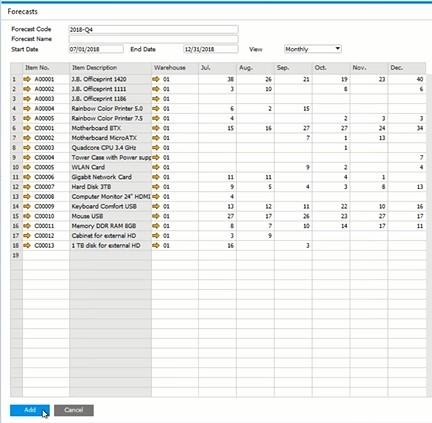

When we save and close, our forecast is created automatically and displayed. This forecast will be used by the MRP runs.

OptiProERP offers a variety of algorithms to choose from. Once you select the range of items and click the forecast icon, the intelligent system starts evaluating the historical events of data and displays the forecast in a graphical scenario.

These intelligent algorithms let you make meaningful decisions by predicting future demand and analyzing the historical values by using smart algorithms.

Intelligent Forecasting with OptiProERP offers you three primary algorithms:

- Automatic forecast – Analyses trends, fluctuations and seasonality to advanced statistical analysis to predict a forecast

- Linear Regression – forces the model to be a simple or multiple linear regression on time

- Triple Exponential Smoothing – Advanced forecasting features make use of historical data (in which the user can add additional inputs) to predict future values

By leveraging the advanced analytic power of SAP Business One HANA, businesses get access to many enhancements. With insightful charts and easy to use functionality, you can manage big chunks of data on the fly and contribute to the organization irrespective of the time and distance. This is the reason why businesses are investing in intelligent ERP software.

OptiProERP is built on SAP Business One, a modern ERP platform which helps businesses improve the accuracy of their forecasts. You can read more about Time Series Forecasting in our blog – How does Time Series Forecasting in SAP Analytics Cloud work.

Follow Us