Digital transformation is the integration of innovative digital technologies into all areas of a business to improve the customer experience and core operations. It’s about finding new ways to generate value and promote overall business efficiency.

There are many ways in which manufacturing companies can adopt digital transformation. For example, they might introduce cloud computing, Artificial Intelligence, Machine Learning, or other robotic technologies to enhance customer experience. It requires a shift away from traditional thinking and leads a path towards collaborative and experimental approach.

Included in this blog:

- Overview of ERP Software And Its Importance In Digital Transformation

- Digital Transformation via a Future-Ready Manufacturing Cloud ERP Platform

- Role of ERP in Digital Transformation

- 7 Signs it’s Time for You to Choose a Modern ERP over a Legacy ERP

- Developing An Effective Digital Transformation Strategy

- Keep Your Focus on Your Goals

- Ways Digitalization is Transforming Manufacturing

- 7 Ways Cloud ERP Helps Drive Digital Transformation in Manufacturing

Overview of ERP Software and Its Importance in Digital Transformation

Enterprise Resource Planning software, an integrated business management tools is essential to the digital transformation process. It unifies all business data into one system and enables automated information flow across departments. However, if a legacy ERP system is holding back your business in this fast-moving environment, you should consider a digital transformation strategy.

Digital Transformation Via a Future-Ready Manufacturing Cloud ERP Platform

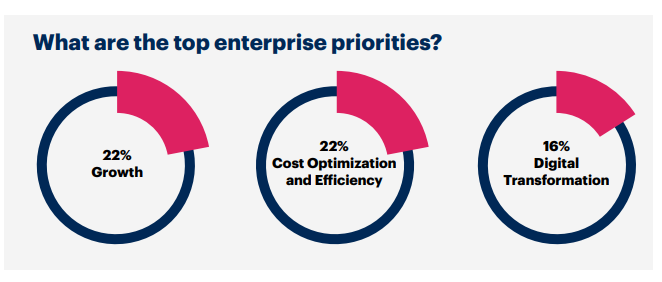

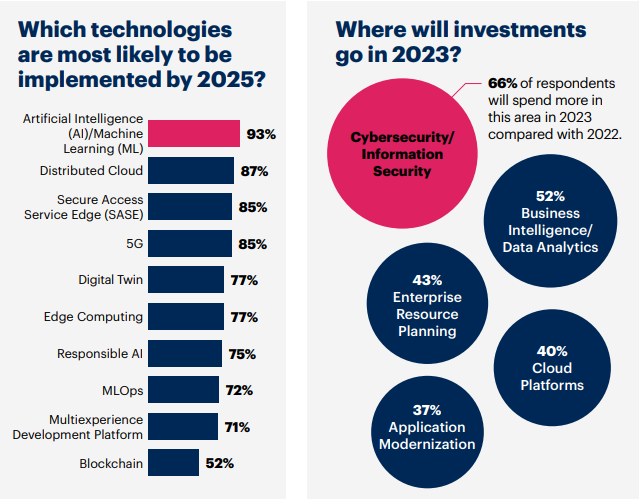

Manufacturing leaders should know what trends will impact their ability to sustain and expand value generation in 2023. Among the many features and functions to consider when reviewing ERP platforms, these three are the most important to digital transformation:

- Make sure that your selection is a manufacturing-specific ERP that produces end-to-end business processes and manufacturing management

- Look for a digital platform that’s future-ready with real-time visibility, intelligent automation, advanced capabilities, continued innovation, and more

- Demand that your ERP leverages real-time insights into every part of your business, from sales quotes to shipping and delivery

Source: Gartner

Role of ERP in Digital Transformation

Among the various tools available for business, ERP stands out as the key enabler of digital transformation. Let’s take a look at the vital role ERP plays in digital transformation and why it is critical for manufacturing organizations.

1. Integration of Business Processes

ERP system serves as a centralized platform for keeping business data and managing it. It provides a unified business view to decision-makers and eliminates data silos by streamlining complicated business processes. ERP drives digital transformation by serving as the foundation for agile and connected processes. Also, it fosters cross-functional collaboration, breaks communication barriers, and promotes teamwork.

2. Real-time Visibility and Analytics

Organizations need an ERP system that provides a 360-degree view of their business, allows customer interaction, and enables personalized service. It empowers organizations to deliver improved customer satisfaction and build long-term customer relationships. This leads to better reporting, monitoring, and improved performance.

3. Automation and Process Optimization

ERP automates mundane tasks and makes data easily accessible to all users tasks. With integrated applications such as financials, production, sales, purchase, warehouse management, and more, ERP eliminates data silos and enables communication and easy data flow across all departments. This leads to proper optimization of processes.

4. Customer-centricity and Improved Experiences

Digital transformation is not just about internal process optimization but also about delivering exceptional customer experiences. ERP systems are pivotal in enhancing customer-centricity by providing a 360-degree view of customer interactions. By integrating customer data from various touch points, ERP helps organizations gain insights into customer behavior, preferences, and needs. This knowledge empowers organizations to deliver personalized experiences, improve customer satisfaction, and build long-term customer relationships.

5. Scalability and Flexibility

As organizations grow and adapt to market dynamics, they require systems that can scale and evolve with their changing needs. ERP systems offer the scalability and flexibility required to support business growth and accommodate evolving requirements. Whether it’s expanding into new markets, adding new product lines, or adapting to regulatory changes, ERP systems can be customized and configured to meet specific business needs. This adaptability ensures that organizations can seamlessly integrate new technologies, processes, and business models as part of their digital transformation journey.

7 Signs It’s Time for You to Choose a Modern ERP Over a Legacy ERP

- It takes employees too long to perform their tasks

- You need mobile access to information

- You can’t keep up with changing regulations

- You have disparate data from poorly integrated systems

- You can’t get critical data fast enough

- It’s becoming difficult to meet customer demands

- Support is costly and hard to get with your current system(s)

Developing an Effective Digital Transformation Strategy

A digital transformation strategy is a detailed plan to improve business operations. It lays the groundwork for a company to establish the why and how of digital technology.

1. Determine What You Want to Achieve

The first thing to consider is your organization’s strategic goals in the next 5 to 10 years. You need to know what you want to achieve before figuring out how to achieve it. You’ll want to start with a bigger picture and then break it down for the short and long term. Everything you’ve defined is then put in order of priority to make it easier to execute.

The goal of digital transformation should be, not just to implement new technologies, but to transform the business as a whole. Digitalization can help you make better decisions with the help of business intelligence, find new revenue sources, gain a competitive advantage, and be more agile as an organization. To achieve such goals, you need to define them well, as they will drive your strategy.

2. Transform Your Processes and Culture

As you prepare for digital transformation, you should also take the opportunity to improve your operational processes. You’ll want to review workflows in all departments to find problem areas. Determine how processes can be adjusted to achieve greater efficiency. Map them out to uncover blind spots to correct. Look for gaps in your data. Examining your processes is essential to help you get the most out of your transformation.

Digital transformation will provide significant changes. Changing the culture of a company isn’t an overnight scenario. It’s something you need to plan for as part of your transformation. It will take time, and management must empower their staff to work in new ways. More skill sets may also need to be acquired to align with the transformation’s goals.

3. Focus on the Customer Experience

Consider options that can improve their satisfaction. Mobile apps, chatbots, a customer portal, etc., are items that can help enhance the customer experience. Examine the entire customer journey to understand their needs. Look at what other companies are doing successfully and listen to customer feedback and other sources to determine how to best implement positive change.

4. Establish Buy-in Company-Wide

Your employees need to feel optimistic about the digital transformation. If they don’t, it will be difficult for them to adapt to the changes and support the company’s goals. Buy-in should start with management. They should stand behind the transformation, show enthusiasm, and get staff excited about the change. Employees must feel optimistic about the transformation and understand how it can help them in their roles and benefit the organization.

5. Define Metrics to Measure Success

With any company initiative, you should be able to evaluate its success. When you invest your time and money, you want to measure your return on that investment. Define productivity, processes, costs, new revenue, and customer satisfaction metrics. See if they improve in a positive direction and by how much.

Once your technologies are implemented, observe to what degree they are being used by your staff. You will not see the desired results if the adoption rate is low. If the adoption rate is low, find out why. Determine if employees have difficulty understanding how to use the system or are simply unwilling to adapt. Either way, it’s something you’ll want to address proactively.

Keep Your Focus on Your Goals

Remember to refer back to your goal as you work through your strategy. There are many options – which can be overwhelming – but you want to focus on what will best achieve your goals. Keep your customers in mind and strive to meet their needs today and beyond. Think of how you foresee your business evolving in the next decade.

- Determine what you want to achieve

- Focus on the customer experience

- Establish buy-in company-wide

- Define metrics to measure success

How Digitalization Is Transforming Manufacturing

Digital technology such as Artificial Intelligence, Machine Learning, Cloud, and more helps companies compete better by improving performance. Below are four ways digitalization is transforming manufacturing:

- End consumers are more empowered

- Transparency is rewriting how OEMs work with suppliers

- Business models are growing more flexible

7 Ways Cloud ERP Helps Drive Digital Transformation in Manufacturing

There are two types of ERP systems that are most common– on-premise and cloud. On-premise ERP works on a company’s servers and is maintained by their IT staff. Cloud ERP is hosted on the vendor’s servers and is accessed via a web browser.

Cloud ERP has become important for digital transformation since it is more agile and allows the utilization of Industry 4.0 technology to include IoT, AI, Big Data, and Machine Learning. Below are the components of Cloud ERP that help with innovation and transformation and that provide a competitive advantage.

- 1. Security– Data isolation architecture in the cloud is secure and enables faster data access. A multilayer approach for security protects your most valuable asset – your business data.

- 2. Interoperability- Cloud ERP helps you connect across the organization so there is collaboration between departments and everyone is using a single source of data. It can also integrate with other applications that may already exist in your organization or that you may add as your business scales.

- 3. Configurability- With Cloud ERP you can set up the system to work the way it makes sense for your business. You can have your processes, collaboration methods, and documents configured to suit your needs. Digital technologies such as IoT, AI, and Machine Learning can be integrated to increase efficiency and productivity in your manufacturing operations.

- 4. Usability– Cloud ERP has an easy user interface, so it is simpler to get up to speed on the system, and implementation is easier and faster, so IT staff doesn’t need to be involved much, if at all. The vendor also handles updates and maintenance, eliminating the need for assistance from in-house IT staff.

- 5. Globalization– Businesses are entering global markets and expanding into new geographies and ERP is needed to support country localizations and multiple subsidiaries. Modern cloud ERP enables seamless data sharing across operations, business units, and global enterprises.

- 6. Analytics– Cloud ERP provides powerful analytics so you can view in real-time how different areas of the business are performing. You can also try various predictive outcomes to help with forecasting. It supports all types of key performance indicators (KPIs) so you can measure tasks, quality, cycle times, and more.

- 7. Agility– Cloud ERP helps to streamline workflow and provides fast access to the data you need to make quick yet accurate decisions. It provides mobile access so your staff can work on the move, whether it be from another location on the plant floor, at a customer site, from an airport, or at home. It allows your business to scale and add more user licenses or modules as it grows.

If you want to learn more about how a manufacturing cloud ERP can help your business with digital transformation, please contact us.

Follow Us