Digital Transformation Is Sneaking up on You!

I received a bit of a shock on the September 27th , 2018. I discovered it was Google’s 20th Birthday! You see, I have been in the IT industry for more than twice as long as Google has existed, and yet I can hardly remember a time when I didn’t use it multiple times every day.

That’s the reality, isn’t it? New technologies have a habit of sneaking up on us, becoming a part of our lives without us even realizing it. It’s the same with digital transformation in the workplace, and particularly in the manufacturing environment.

Digital transformation is exactly what it says – where you start adopting the digital tools to bring your business into the 4th industrial revolution, to become flexible & agile, informed & responsive. What none of us can pretend is that this is all something “out in the future”. The future is indeed now, the business models you work within are changing, and changing rapidly. You need to be ready. The opportunities are tremendous, and if you do nothing you could find yourself not just left behind, but left out.

Sound scary? It doesn’t need to be! The tools you find in Intelligent ERP are all things you are at least somewhat familiar with. And that’s the other point to keep in mind – Intelligent ERP already has these tools, and that is exactly what they are, tools to work with. You don’t need to re-invent any wheels, you just need to learn how to use them, to understand the concepts and put them to use.

Before we look at the technologies that drive digital transformation, lets focus on an extremely important difference in the new connected world. Its all about people, not systems and processes.

Your business is no longer at the center of your universe. It is now about how you engage with your universe that is important. The world is connected as never before. The average person has around 24 different digital IDs – they could be LinkedIn, Facebook, Google, etc. In the developed world, that means there are around 55 billion of these digital IDs to engage with. This obviously creates new challenges in how you market to your target customers, how you sell to them, and how you maintain communication with them.

The implications for business, and society in general, are many and varied. Here are some of them:

- The new nature of communication is about sharing experiences.

- The way you generate revenue and get paid for what you do is changing. This is a reality for us too – where we used to sell software licenses up front, we now frequently charge a monthly fee for them on a subscription basis.

- Marketing has moved from trade magazines to social media.

- Listening to your customers is now critical – they will give you the innovation to move ahead of your competitors – and some of that may even be coming from social media feedback and comments.

- An intelligent machine you sold, that tells you when it needs service or repair, is a game-changer. It gives you the ability to retain service revenue at the expense of third-party repairers, for example.

It is the same with your staff. How your staff carry out their work, and where they do it using mobile technologies, is a reality. Nearly half of all American workers now work remotely at least some of the time. As globalization accelerates, employees can be anywhere in the world and in any time zone – they need to all be connected, securely, all the time.

One of the foundations of digital transformation is the digital workplace. Put simply, it is a unified collection of solutions, apps and tools that provide an environment where your employees can be more productive and engaged. Not all these solutions and tools will be part of your ERP system, but it should probably provide a single place from which everything can be accessed. The personal cockpit for each user in the SAP Business One platform does exactly this – even other apps can be added to your cockpit.

Why do we need it? To be productive, we all need to play well together in the same sandbox! IDC says a third of our email time is wasted – reading “reply to all”, locating attachments, searching for emails that have important information in them – that’s around two and a half hours per week. Having that information in an easily-searchable document repository instead of in multiple workstation local drives is a help. IDC also says we spend around 12.5 hours per week duplicating or re-creating work that has already been done, and a further two and a half hours searching for information and the people who have it locked away on their local drive or in their heads. That’s getting close to half a working week wasted, and the cost is more than $20,000 per employee per year! Collaboration through tools like Google Docs, Drop Box, etc. are essential to changing the culture towards productivity. So, the digital workplace is all about connecting people to processes, people to information, and people to people. It almost always needs to be in the cloud to connect all those who need to work remotely.

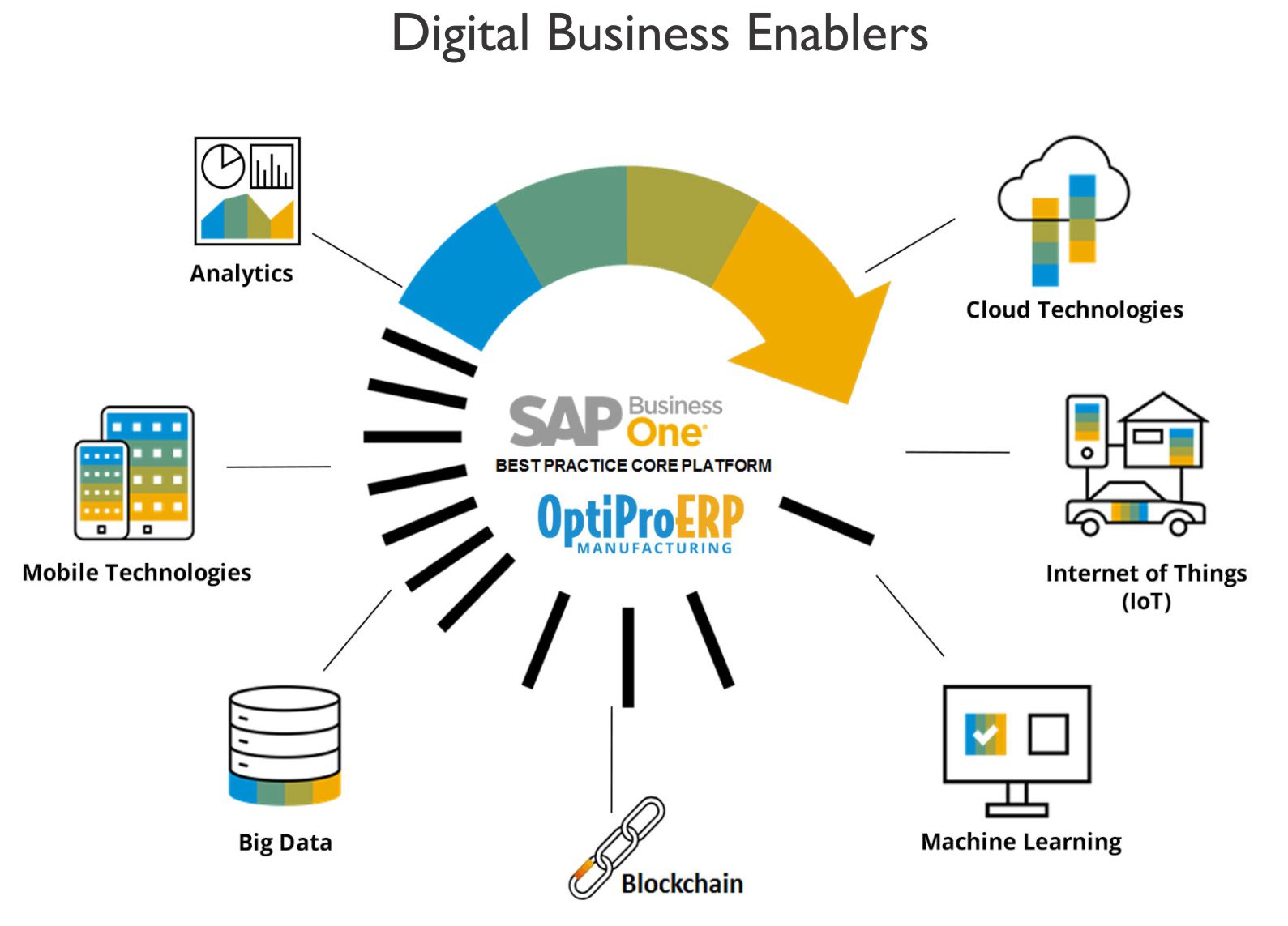

Putting the enablers in perspective.

Lets look at the enablers of digital business – analytics, big data, machine learning, cloud technologies, mobile technologies, and the internet of things (IoT).

Analytics

If you extract data into a spreadsheet and start playing with it using pivot tables and formulas, you are analysing data. Much of the data analysis required, to find the information for decision-making, in many manufacturing companies is done this way. The problem is, it is never current, and it is usually kept on someone’s workstation.

Intelligent ERP has all the tools needed to overcome these problems. It is centrally held, so is available to all those with the authority and need to view it. Drag & drop dashboards with instant drill-down to the underlying data can be used collaboratively, even in meetings. Dashboard layouts can be saved for later recall, and the links distributed to a wider audience. This is the most basic level of analytics, it makes self-service reporting with access to current data a reality, it takes just minutes to learn how to use it, and it is something any company can start with right now.

Truly Intelligent ERP, such as OptiProERP , offers much more. Predictive analytics is a step up, but it is not something you don’t already encounter daily. Think of the digital assistants you probably use every day, like Apple’s SIRI, Microsoft’s Cortana, etc. The user experience becomes assistive. Predictive analytics assess the options and advise the best course of action. Automated Q&A systems to find what you need are advancing to conversational styles, as chat-bots and digital assistants advance to anticipating your needs and goals.

Where can you use this right now? Forecasting is traditionally a guessing game, based on past history, the optimism (or pessimism) of sales staff, a reading of market reports and economic predictors, etc. There is a very high human input that is seldom scientific in nature. Predictive analytics uses algorithms to analyse all sorts of data and look for patterns to take out the guesswork. Data scientists build these algorithms for big companies. OptiProERP already has such algorithms inherent in it, because SAP put them into the SAP Business One platform for you, the platform that OptiProERP is built on. If it is already there, and it is cost-effective, why wouldn’t you want to start using it?

Future uses of predictive analytics are as broad as your imagination. By analysing manufacturing and assembly times for existing models, you can accurately predict the costs for a new model, enabling easy costing before you start production. Mean-time-between-failure calculations can become eerily accurate. There are so many more examples.

Big Data

The difference between big data and the data you are used to working with is not merely the size – although size does matter!

What makes it so big is the types of data it can accumulate for analysis. It can be any voluminous amount of data – structured (such as an SQL database), semi-structured (such as streaming data from sensors), and unstructured (such as document files) that has the potential to be mined for information. Again, Intelligent ERP has the ability to accumulate and analyse this data – you just need to work out how much you want to have, and where to store it.

Imagine being able to Locate your business information via freestyle search, and drill down to the documents and sources.

Because big data is just that – extremely big – most companies analysing it use public cloud computing for the task, where they pay only for the storage and computing time needed – which can be turned off when not being used. Most companies could not afford to own and manage the server clusters required for this level of processing.

Machine Learning

Machine learning takes automation to a whole new level, one where tasks necessarily involve decisions to be made, and where the machine can make those decisions for you. For less routine tasks, where human intervention is required, machine learning augments the process by reporting signals that may lead to disruption.

Again, this is something you are already familiar with. Facebook looks at your likes and Google searches, and finds advertisements to annoy you with by filling up your news feed.

Applications already available in OptiProERP include: Product recommendations based on the buying histories of your customers, and similar customers, in sales documents; and Intelligent Forecasting – interacting with built-in statistical forecast algorithms to analyze inventory levels and optimize your demand.

Cloud Technologies

Does the idea of putting all your applications and data on a computer other than one locked in your own premises scare you? Did you know you probably use cloud applications every single day? Gmail, Facebook, & Dropbox are all cloud applications. So are iCloud, Flickr, One Drive, Instagram, Netflix, YouTube, amazon.com, PayPal, Skype, and so many more. In fact, all social media is cloud-based. It is likely you transfer photos from your smart phone to the cloud for safe-keeping. Paying your bills online is a cloud application.

The cloud has become an integral part of our personal daily lives, in our routines of communicating, exercising, commuting and entertaining.

Many reviewers thought the iPhone was too expensive and too pretentious to survive in the market – they were measuring it against other simple mobile phones. Of course, they were wrong. Almost everyone has a smart phone on them these days, and they do so much more than merely make phone calls. We connect to the world with them, we can even do lots of tasks related to our work with them.

This is the major reason why too many companies do not consider the cloud when implementing ERP systems – they measure the TCO against a server in their own office.

What they fail to factor in is the opportunity cost of operating in the cloud. Some of these are:

- Scalability: No matter what changes increase or decrease your organization’s size, be it expansion, acquisition, or reorganization, operating in the cloud removes all the upheaval such changes can entail.

- Tax advantages: Cloud operations are an expense, not a capital cost.

- Predictable costs: Mostly per user or per Mb costing, easy to quantify and understand.

- Evergreen: Your vendor will normally keep your software updated to the latest version, and its usually done while you are asleep.

- Disaster recovery: If your office burns down, you can be up and running again in minutes because your apps and data didn’t go up in flames.

- Remote users: Access via browser to the cloud is a whole lot easier than maintaining your own VPN (Virtual Private Network).

- Advanced features / New applications: Some advanced features can mean expanded infrastructure – with the cloud you already have it. New applications can be made available quickly, and with minimum disruption or IT input.

- Flexibility: Want to try some new things related to digital transformation? Cloud gives you the flexibility to experiment, evaluate, and adapt new technology far more effectively than having to install them in-house.

Here’s another very important consideration: try purchasing a cheap, non-smart phone just to make phone calls. There are very few options, and they mostly run only on 2G networks. You might well ask, why would you want to, unless you want a burner phone for nefarious purposes? A valid question – almost everything we want to do with our devices these days requires a smart phone. It’s the same with the future of computing – Intelligent ERP, and all those apps that enable digital transformation, are being developed for the cloud only. If you are not operating in the cloud, your future choices are severely limited, or soon will be.

Mobile Technologies

Many people don’t relate industrial mobile technologies to the smart phone in their pocket – or their hand – but that is exactly what it is. Whether it is a geometric 3D scanner communicating with your quality control results screen, or a machine on the other side of the world telling you it needs an urgent repair, the technology is exactly the same as you calling, or sending a text to, a colleague.

Intelligent ERP solutions operate on any device – desktop, laptop, tablet, or phone. This means you can avoid the manual processes that result in misinterpreted and duplicate entries when you have disconnected systems.

The real business opportunity lies in allowing operators and technicians to have access to data not just from control rooms, but from anywhere and at any time, using tablets, smart phones, and similar devices, enabling them to make transactions from almost every place on the earth.

Since all you need is your smartphone or a tablet computer, what would stop you empowering your staff right now?

The Internet of Things (IoT)

That 3D scanner we mentioned above, and the smart machine are “things”. This is nothing new. My daughter’s new house is a “smart home”. She has an Amazon Echo connected to the cloud-based Alexa system which also controls all the smart devices. She can walk in the door and say “Alexa, turn on the lights” and on they come. She can turn on the lights, or the oven, from her smartphone. So, the IoT is simply the connection of many smart devices via the cloud to your system.

Your staff can operate OptiProERP by voice using Alexa, a big help when you are buried in a repair or complex assembly on the shop floor.

Here’s a simple scenario:

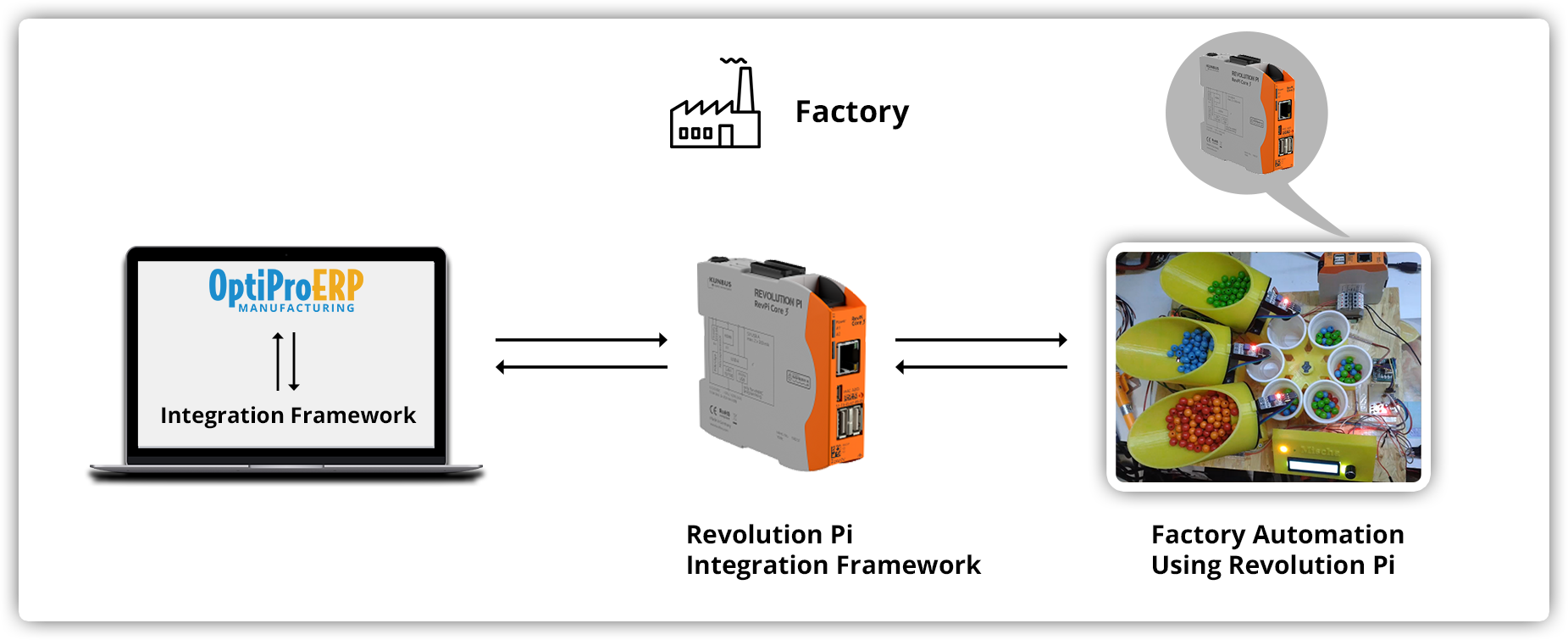

It uses the sap.B1FactoryConnector to send orders to production and obtain results back, and the B1i-FactoryController to monitor the production process and send the feedback to the Connector, including any alerts and error handling. Both of these components are free in the Integration Framework in OptiProERP, courtesy of the SAP Business One platform.

Its quite possible you have sensors measuring important QA data, or counting finished products off the line, that you know about but haven’t connected to. Its time to start using that data, to get more accurate QA data, to update your system without having to key in that data.

OK, I’m hooked – where do I start?

So that’s the new digital world. You need to figure out your place in it.

It is important to understand that digital transformation is a process, and not a switch you turn on. It typically requires organizations to create a digital strategy that is both incremental and dynamic, allowing for the inevitable shifts along the path as advanced technology discoveries continue and the marketplace changes. So where do you start on this journey?

It must start at the top. Any digital transformation project must start with those people who own or set the overall direction for your business.

You need to gaze into your crystal ball and determine what your future holds. Where do you want to be in 5, 10, or more, years?

Think about which of these new technologies could make a difference to your business, and what the advantages of using them might be. Be brave! Dare to dream big at this stage.

Be prepared to reach compromises – about what you can do now, how much you can cope with, remembering that you aren’t always going to get everything you want.

Where are you now? Do a survey of your current technology and automation environment to establish your starting point, and identify what systems and technologies you currently have in place that can play a role in your future.

Identify your opportunities. Where are your processes lacking? Too long to get products to market? Unable to react to demand trends? Resources over-burdened? Prioritize the biggest challenges.

Start small. Wholesale change is disruptive.

Work with your ERP vendor. You probably don’t have a clear vision of what Industry 4.0 looks like in your market, and the related technologies are still evolving. But do your best to envision how technology is changing your industry. Look at your competitors, especially the biggest companies and the most innovative ones. Research the technology suppliers, and read about their successes, particularly in your market and similar industries. Talk to the vendors, get them to explain the technologies, and help you determine where you can use.

We needed software that was actually a 21st century solution, software for the digital age that would help us as a manufacturing company.

– Mike Nanda, Owner & President

Embrace the cloud. The cloud is where digital transformation happens. It is also where the majority of development for digital technologies is focused – don’t get left out!

Continuously improve. Continue to build out your digital strategy plan.

So, why do you need an Intelligent ERP solution?

In a single word, access.

How do you drive all these new technologies, and where from? The reality is, only an intelligent ERP solution can provide the platform to unify all the components of a truly digital business. You then need to ask “Can I do it with what I have now?” The likely answer is that you can’t. Most legacy ERP systems simply are not capable of handling this sort of transformation.

How does OptiProERP qualify?

The secret is the SAP Business One platform on which OptiProERP is built, and extends. The SAP Business One Platform already has all the enablers you need for digital transformation – handling of big data, predictive analytics, the algorithms required, and mobile capabilities. It has a complete integration framework to connect to smart factories and the Internet of Things. This is not something planned for a future release – the integration framework is a reality and available right now, and it is part of the standard software.

Its over to you now, you see the benefits, let us help you realize them!

Find out how OptiProERP can transform your business by emailing us at optiproinfo@optiproerp.com or by requesting a product overview.

Follow Us