When businesses use disparate systems that don’t “talk” to each other, it takes a lot of employee time to gather the data needed to see trends, track profitability, and make business decisions. Information is isolated within departments, and employees don’t see the whole picture of what is happening in the company. Staff can only access data about their department, which causes challenges because they don’t have a 360-degree view of operations and can’t communicate with other business areas.

As manufacturers scale their operations, their processes become more complex. This complexity, coupled with the inefficiencies of operating with disparate systems, leads to a significant waste of time and resources in accessing crucial information. That’s when the benefits of a manufacturing ERP system begin to become apparent. This blog explores the challenges of disparate systems for manufacturers and the benefits of an ERP system to help with revenue and growth.

Challenges from Disconnected Systems

1. Limited Access to Data

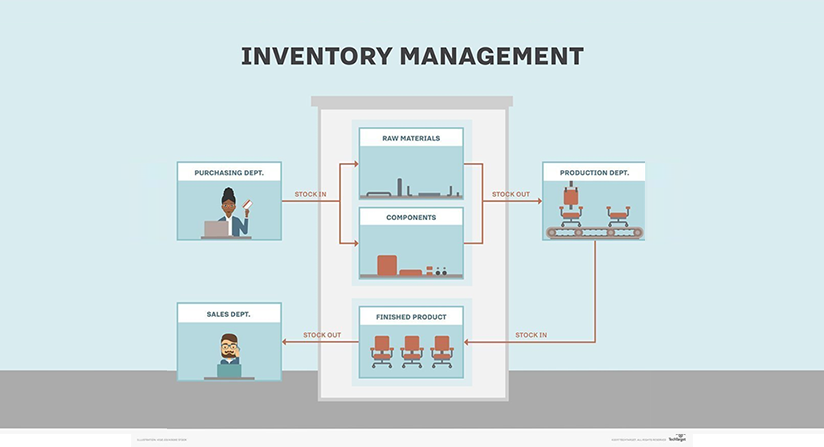

When information is fragmented within a business, it is impossible to work efficiently. For example, to know what inventory is available, you would need to check with the warehouse for items in stock, with production for work in progress, and with procurement for items scheduled for delivery. That’s a lot of steps to understand inventory, and then it still could be incorrect. Data is gathered from different systems for reporting, and the information could change by the time the report is compiled.

2. Discrepancies

If inventory isn’t accurately calculated due to data discrepancies, sales might promise a delivery date based on incorrect inventory data. Additionally, production could be delayed if there is a miscommunication regarding material availability. If materials aren’t available when needed for production, equipment and staff could be underutilized, causing significant inefficiencies. Having data in two or more systems can lead to inconsistencies. For instance, a customer order could be shipped to the wrong address because the shipping software wasn’t in sync with the order entry system. These situations hurt customer satisfaction and the bottom line.

3. Miscommunication

With disconnected systems, the risk of miscommunication is high. Misinterpretations occur when information is exchanged manually between departments. This can affect updates on order changes, inventory levels, or production schedules. Communication gaps can lead to frustration and hinder overall collaboration, underscoring the need for a more efficient system.

4. Inefficiencies

Not having inventory in the right place at the right time can cause production bottlenecks and increase product lead times. Disconnected systems also cause duplicate data entry and lack streamlined processes. Since information is siloed, everyone has to work harder to find what they need. Customers won’t receive fast service since their information is not quickly available. Staff must be trained on multiple systems, which takes time and can be challenging when using different interfaces. It also causes employee dissatisfaction.

5. Higher Costs

The items listed above, lack of access to data, discrepancies, miscommunication, and inefficiencies cause higher costs. Employees spend more time doing things for an increased labor cost, and machines are underutilized, which means the company isn’t getting its money’s worth from them. Discrepancies cause mistakes, resulting in more significant expenses from production rework, rush shipments, inventory overstock, and employee overtime. IT staff has to manage many systems, which can be complex and expensive.

Benefits of Manufacturing ERP for Increased Revenue and Growth

So, how does ERP help the manufacturing industry to improve revenue and growth? ERP has many benefits for manufacturing businesses to help them compete better and recognize growth opportunities. Below are the critical benefits of a manufacturing ERP system.

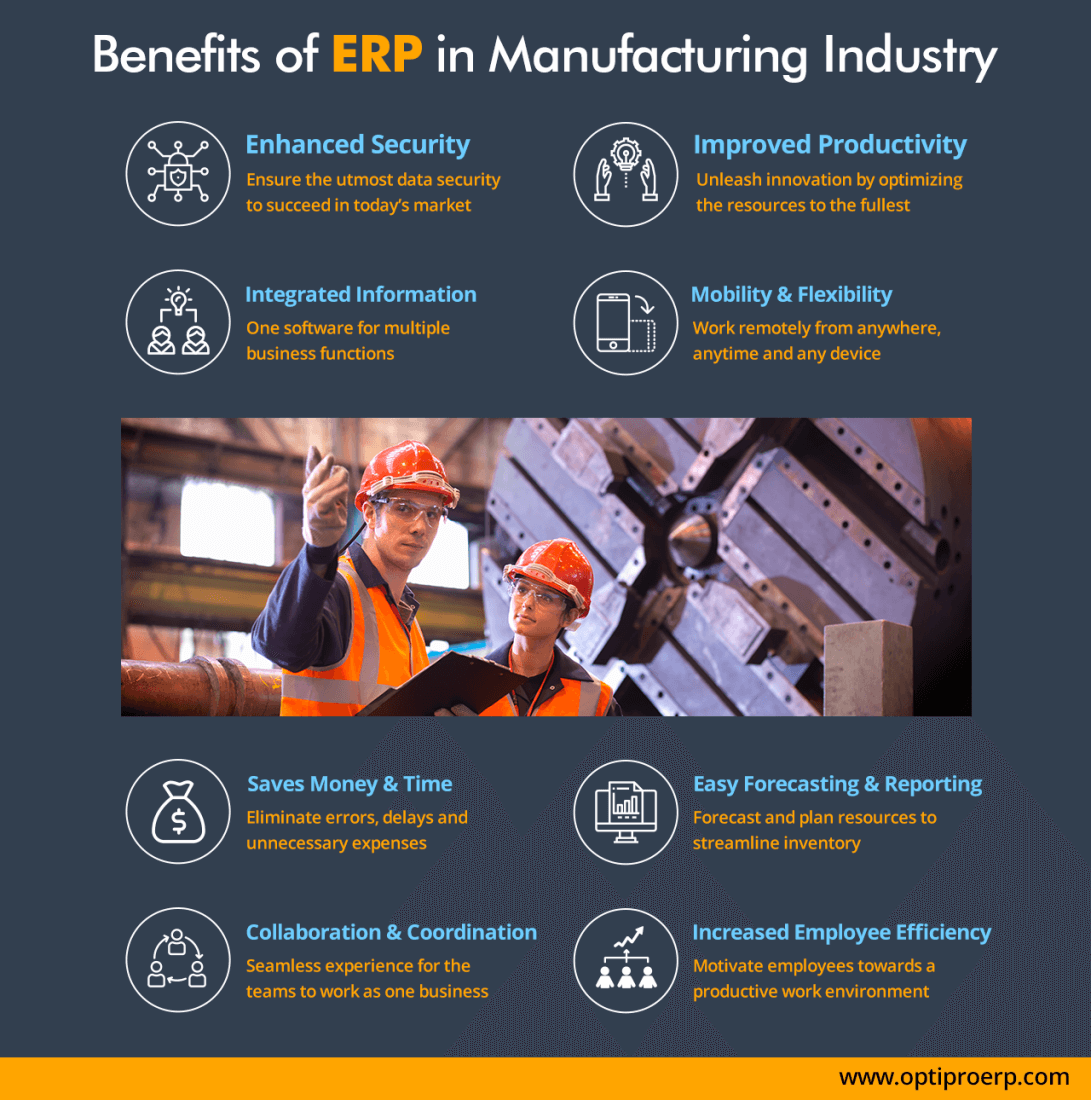

1. Greater Productivity

A manufacturing Enterprise Resource Planning system streamlines processes for increased productivity. It uses best practices to manage workflow effectively. ERP automation lets work happen at a much faster pace. It provides information for employees to do their jobs better and quicker, which improves satisfaction. Reports can be created in seconds, and dashboards allow managers to understand how the business is performing at any time. Inventory is optimized, and materials are available for production as needed. Advanced planning and scheduling ensure output and resources are utilized effectively. Efficiency is increased due to improved workflow, so it takes less time to do things than before. Everything is connected and working together cohesively.

2. Real-time Data

With a manufacturing ERP system, businesses can immediately report on almost anything they need to know. Everything is housed in one database for a 360-degree view of business operations, and everyone accesses the same accurate information. As a result, errors are reduced, and employee collaboration is improved. Managers can see production status, and that information is available for procurement, sales, and customer service to keep needed materials in stock and customers updated.

3. Increased Product Quality

Manufacturing ERP has quality built into processes from receipt of materials until the final shipment. Everything is connected, and alerts are generated if there is a problem. Keeping quality levels high improves customer satisfaction and keeps expenses low. It helps to eliminate the need for rework and overtime. It also enhances employee satisfaction since they can quickly know when something is wrong and not have to correct it later.

4. Better Decision-making

Manufacturing ERP helps staff make informed decisions based on fast and accurate data. It drills down to provide deep insights into business performance to understand ways to improve production planning, pricing strategies, and allocate resources. With manufacturing ERP, you can quickly generate customized reports in all crucial areas to measure KPIs for operational effectiveness and identify areas needing improvement. Disconnected systems can produce reports in seconds rather than hours or days, so managers have the information when required. Executives can see trends and opportunities and capitalize on them when it is most advantageous. It is easier to gain traction in manufacturing when you have insightful data at your fingertips.

5. Optimize Inventory

With a manufacturing ERP system, you can view inventory levels at any time and know precisely what is on hand and where. Materials can be tracked from receipt until shipment using scanners, mobile devices, SKUs, or barcodes. Procurement receives information on inventory so they know when to order more. Forecasting can evaluate seasonal changes or trends to determine material requirement planning better. Manufacturing ERP optimizes the supply chain to ensure the proper lead time for materials ordered and to recognize the best vendor for which to place the order. Utilizing a vendor portal, you can easily communicate with vendors, and they can access order requests or other information as needed. Everything is coordinated and organized to ensure the proper inventory is on hand.

6. Improved Employee Collaboration

With everything connected in manufacturing ERP, employees have one version of the truth. They have access to information in real-time and can communicate easily with one another. Everything flows smoothly from department to department, and there is no distrust of the quality of information. Employees can work more collaboratively together to resolve issues. Employees become overall happier in their jobs as there are fewer steps to do their work, and they are no longer isolated from other departments.

7. Strengthen Customer Relationships

With manufacturing ERP, sales can access accurate inventory levels before quoting a delivery date, preventing order fulfillment issues. Customer service can see the status of orders and other customer information to answer their questions promptly and correctly. Marketing uses insights into customer behavior to better understand what is working and what products or services are most popular to create campaigns accordingly. Customers can access their information through a customer portal to make payments, check order status, etc., for greater satisfaction. Everything in the business is integrated and optimized.

8. Remote Work Capabilities

During the COVID-19 pandemic, many businesses struggled to stay afloat because they could not allow employees to work remotely. In today’s mobile-driven world, employees expect that they should be able to work off-site. Sales staff should be able to look up customer information or create transactions when traveling. Service staff must be able to access tickets and enter data on the road. Managers should be able to keep tabs on business performance if they are off-site and approve or deny employee requests.

Conclusion

Manufacturing ERP increases companies’ revenue and growth by providing better control over costs, improving functionality and productivity, and enhancing visibility. It allows companies to expand after implementation and well into the future. The advantages of ERP software enable businesses to compete, grow, and prosper more significantly than disconnected systems. To learn how to choose the right ERP system for your business for increased revenue and growth, download the Roadmap for ERP Selection in Today’s Digital World.

Follow Us