Manufacturing ERP software helps manufacturing businesses manage and integrate different business processes and operations, enhancing productivity and improving overall efficiency. It centralizes information from business departments and provides a dashboard so managers can quickly access important data to make timely decisions. ERP helps manufacturers plan, manage, and analyze business operations for enhanced productivity and efficiency.

What is Manufacturing ERP?

An Introduction to Manufacturing ERP Software

Welcome to Manufacturing ERP 101, where you can fast track your understanding of ERP and assess its value for the continued success of your manufacturing business.

What Is Manufacturing ERP (Enterprise Resource Planning) Software?

A connected business platform allows companies to coordinate activities and processes and store data in one central place for a single-source of truth to run the organization efficiently.

Who Needs Manufacturing ERP?

Manufacturing ERP is software for manufacturing businesses of all sizes. Manufacturers need ERP with industry-specific capabilities to optimize operations and connect their manufacturing processes with other departments.

Some key manufacturing ERP modules are inventory management, production management, planning and scheduling, warehouse management, and quality management. Manufacturing ERP ensures all operations are connected and streamlined.

Small Business ERP

ERP for small manufacturers eliminates the need for multiple tools and provides one system that works across the enterprise. It’s an end-to-end solution with best practice processes to manage business complexities. Many small businesses choose a modern cloud ERP system for faster deployment, lower ownership costs, anywhere access, increased security, and continuous upgrades.

Mid-Market ERP

ERP software for mid-market manufacturers offers built-in analytics, rapid deployment, and best practices for many business processes. Modern ERP software provides growing businesses with the tools to be more productive, agile, and competitive.

Enterprise ERP

Large manufacturers with global operations need a robust, leading-edge ERP with embedded AI, machine learning, and analytics. They require a platform that supports intelligent automation to transform processes.

Why Is Manufacturing ERP Important for My Business?

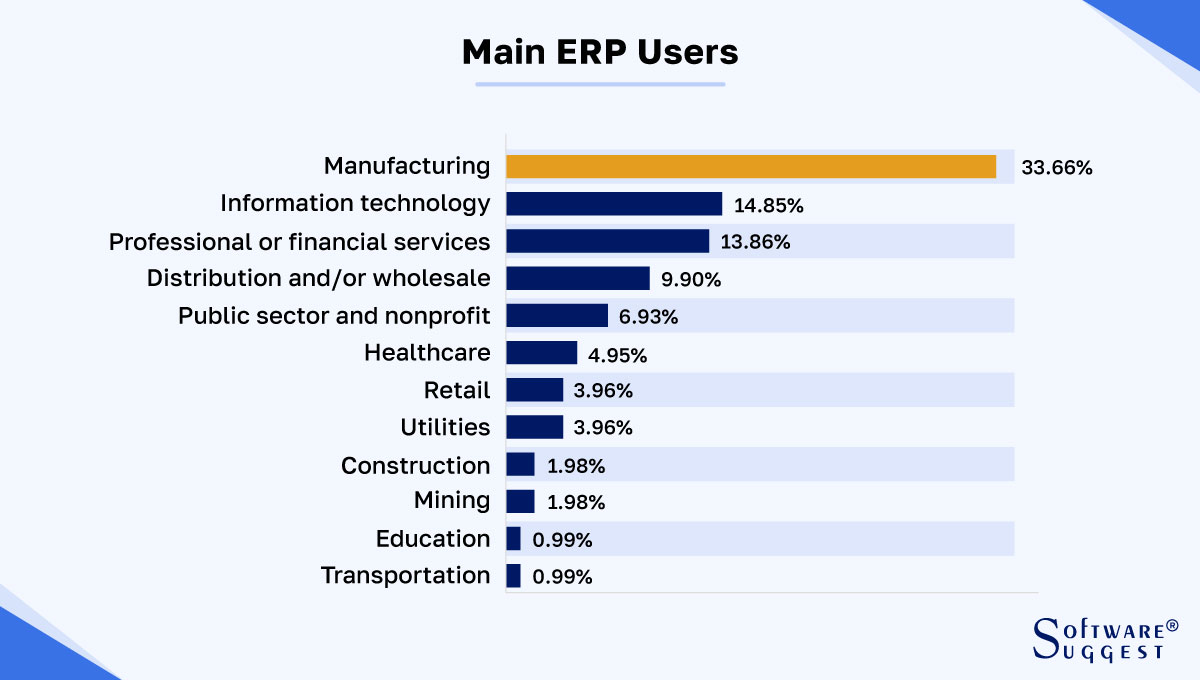

The manufacturing industry has a substantial share (34%) of the ERP market, followed by IT (14.85%) and financial services (13.86%). A manufacturing ERP system offers many advantages over generic ERPs. The most notable benefits of ERP software for the manufacturing industry are noted below:

- Track raw materials, allocate resources, and plan out the production process.

- Manage manufacturing operations more efficiently and track shop floor activities.

- Schedule jobs based on raw materials in stock and available machine time and labor.

- Manage daily finances, create custom reports, and track job costs.

- Monitor the inventory of finished goods.

- Receive, scan in, and store products, and know the exact location of each item within the warehouse.

- Use quality control checkpoints to ensure products meet industry, government, and customer requirements.

- Centralize information across all business departments for increased insight and enhanced collaboration.

- Ensure better customer satisfaction and improve the supply chain.

What Are Common Manufacturing ERP Features?

Is My Company Ready for Manufacturing ERP?

When a sales order is received, there may be many questions requiring immediate attention. These questions, which involve production planning, resource management, and cost control departments, are not effectively addressed by manual processes and stand-alone programs.

- What do I need to manufacture?

- When do I need to manufacture it?

- How do I manufacture it?

- What resources are available for production?

- What do I need to purchase for manufacturing?

- How can I manufacture it efficiently?

- Can I manage the costs of manufacturing it to turn a profit?

- How do I ensure that what I manufacture is of the required quality?

Did You Know?

QuickBooks is used by more than 2 million small and midsize businesses worldwide. If daily business management processes and plant floor activities take too much time, you might be ready for manufacturing ERP with built-in financial management functionality.

Download the ERP Selection Roadmap

Ready to learn more about selecting the RIGHT ERP for your manufacturing or distribution business? Download our guide detailing six things you should consider when choosing a new ERP solution in today’s digital world.

Download the ERP Selection Roadmap

Ready to learn more about selecting the RIGHT ERP for your manufacturing or distribution business? Download our guide detailing six things you should consider when choosing a new ERP solution in today’s digital world.

What Is the Difference Between Generic ERP and Manufacturing ERP?

A generic ERP is designed with a broader set of functionalities that are not tailored to any one industry but can be adapted by various businesses across all sectors. It is built with a one-size-fits-all perspective and usually requires higher customization to meet unique industry requirements.

On the other hand, manufacturing ERP boasts functionality that addresses a manufacturing business’s unique needs and processes. It includes Bill of Materials, shop floor management, supply chain, inventory management, quality control, and more. Manufacturing ERP software integrates all business processes, providing complete visibility and control over the entire organization.

Which ERP Implementation Practice Is the Best for Manufacturers?

Three different types of ERP implementations exist: cloud, on-premise, and hybrid.

Cloud-based ERP

A cloud-based ERP system provides manufacturers with a flexible and comprehensive system with continual IT support, updates, and real-time training. It frees the IT team from managing and maintaining the system as it is managed by the vendor.

On-premise ERP

On-premise implementation delivers ERP applications from your on-site server. The business is responsible for managing software updates, security, and additional IT costs. On-premise ERP requires a greater upfront capital investment plus ongoing system maintenance costs.

Hybrid

This ERP implementation practice allows manufacturers to run some ERP applications in the cloud and some on-premise.

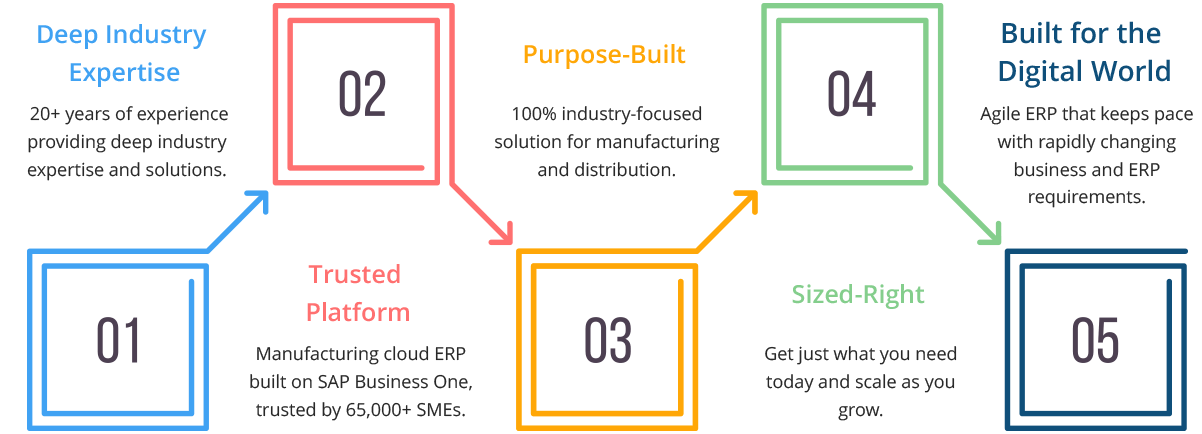

OptiProERP Is Manufacturing ERP on the World-Class SAP Business One Platform

OptiProERP is powerful manufacturing ERP software built on SAP Business One. It is designed to be simple and user-friendly. With role-based dashboards and modules tailored for manufacturers, you can empower your business with improved operations and prepare it for growth.

What Are OptiProERP’s Manufacturing Modules?

Benefits of OptiProERP

Increased Productivity

Automate and optimize your business processes, helping everyone in your organization accomplish more.

Operational Visibility

Get answers to critical business questions with operational visibility from a single system of record.

Informed Decision-making

Act on insights, increase performance, and share results with real-time business reporting.

Reduced Risk

Predict and prevent risk with business visibility and control that ensures compliance with regulatory requirements.

Enhance Agility

Rapidly identify and act on new opportunities. Claim your competitive edge with ready access to real-time data, increased agility, and efficient operations.

Want to learn more about OptiProERP?