Recently OptiProERP attended an international exhibition about manufacturers. Our marketing executive met Harper Sheldon, operations head of a leading manufacturing company and one of our loyal customers during the event. Mr. Sheldon shared his experiences stating the importance of MRP for manufacturing businesses. Read some of what he shared:

We are aspiring to expand our manufacturing business. I have been constantly looking for people in the industry to gain insight. I have spent a great deal of time reading about the best manufacturing business practices. One morning, I picked up Joseph Orlicky’s first edition published in 1975; “Orlicky’s Material Requirements Planning”. Orlicky was instrumental in developing Material Requirements Planning (MRP).

Orlicky explains the purpose of MRP which is to streamline 3 main processes within a manufacturing unit:

- Minimize lead times

- Optimize inventory levels

- Maximize service levels to boost business efficiency

MRP was developed in the 1970s to aid manufacturing businesses to calculate and optimize their material requirements. Later, in the 1980s, MRP (Material Requirements Planning) evolved into MRP II (Manufacturing Resource Planning) covering broader aspects such as invoicing, payroll, capacity planning, shop floor control, etc.

While discussing in our office the useful tools to expedite manufacturing processes, the first question that came to mind is ‘What is MRP in manufacturing’?

Our managers always struggle with the old business problem of balancing inventory levels. The key question asked by our production planners is, “Do I have the right level of inventory?”

MRP automates the planning process to determine how much raw material a business requires based on the projected demands.

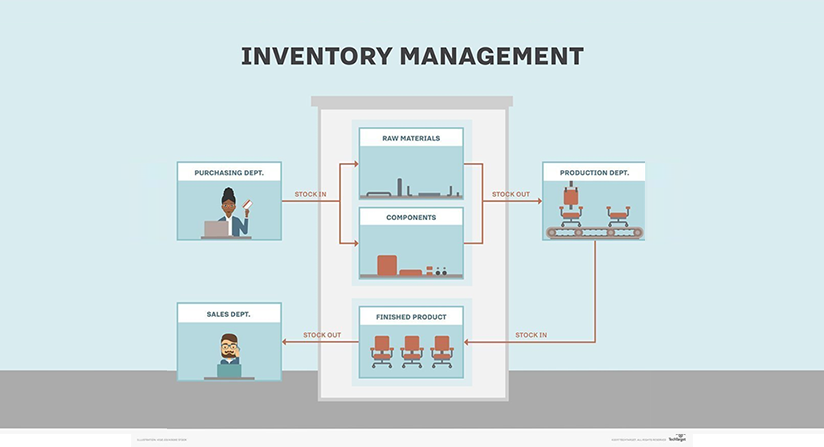

Material Requirements Planning is an inventory management system designed to streamline production schedules and place orders for items of dependent demand. For example, in the case of a bicycle manufacturing business, the dependent demand items include aluminum pipes, tires, seats, bicycle chains, etc.

We always look for answers to three preliminary questions before initiating a production process:

- What components are needed in terms of inventory?

- How much is required?

- When do we need these components?

MRP helps to establish clarity to these questions. It designs a comprehensive production plan for finished goods and estimates the components and raw materials required. It provides a schedule for finished goods that is converted into a schedule of requirements to produce the final product. MRP matches the flow of materials and parts in a phased order considering the production schedule. It uses the information to calculate the material required based on the dependencies of other raw materials. This information combines several variables such as purchase and sales orders, market demands, inventory, BOM, etc.

MRP creates a difference in the manufacturing industry by seamlessly streamlining inventory. It has a common goal to serve and that is to make sure the level of inventory is low but high enough to provide for customer needs!

How would MRP help us in streamlining processes? I asked our company’s research analyst during our conversation.

The research analyst shared some insights on why MRP is important for manufacturers:

- Basically, in a manufacturing business where bulk production is the nature of work, it becomes important to stay on top of the manufacturing processes, and if an error occurs an immediate course of action is taken. MRP allows you to calculate the product cost and time and provides a common platform to follow a customer order from the initial quote until shipment.

- Many manufacturers have benefitted from the best practices of MRP. You can streamline your inventory and track stock movements, serial numbers, shipments, and more in real-time.

- The production manager gets insight into the availability of materials and the time taken for manufacturing operations that include assembly, testing of products, packaging, etc. MRP benefits come from accurate production planning and scheduling processes.

- MRP ensures accurate material planning and purchasing so that you meet regulatory demand and maintain quality benchmarks by giving full visibility into manufacturing processes. You can track product series, manage quality levels, track expiration dates of materials used, and have transparency of the overall processes and standards.

In the 1990s, Gartner coined the term ERP (Enterprise Resource Planning). ERP systems improved inventory accuracy and streamlined business processes holistically. The ERP system included all the processes contained within MRP II while integrating the application with other operations such as Inventory, Financial Management, HR, CRM, and Supply Chain Management.

Unlike MRP which is a standalone application, ERP is a fully integrated system giving you the foundation to scale and compete in a competitive market scenario. I was convinced by my research on the best practices for a manufacturing business. The need to boost productivity and sales is the core objective of every business which depends on better-streamlined processes. MRP benefits merged into an integrated manufacturing ERP solution can change the way businesses work. If you have questions regarding this topic, contact us for free assistance!

Follow Us